While bi-fold doors are an incredibly popular addition to homes across the UK, there is often a misconception surrounding the durability of the bi-folding structure. To help squash any concerns doubting the longevity of bi-folds we’ve created this specialist guide to answer the key question: ‘are bi-fold doors fragile?’

In this guide, we’ll explore the strength and stability of bi-fold doors. We’ll also share our insight into what’s needed to create a robust system which delivers long-lasting performance.

Read on for more.

Do bi-fold doors break easily?

While some systems on the market may not be able to stand the test of time and could be perceived as fragile, this isn’t true of every system.

As a bi-fold hardware manufacturer which has launched a range of high-quality bi-folding systems into the market across the UK, we would never describe a bi-fold as ‘fragile.’ This is because, from our experience, an effective bi-folding system is durable, secure and sturdy.

Exploring the durability of bi-fold doors

As we said above, we have lots of experience designing, manufacturing and launching quality bi-folding systems so we understand what it takes to develop a strong high-performing bi-fold door.

If you’re keen to manufacture your own bi-fold, we’ve learnt a few tips and tricks over the years, which we always follow, to guarantee we create incredibly durable systems which are installed to the highest standard and look fantastic.

Check out the rigorous checks we complete with every bi-folding door below.

Work with strong materials

Exploring the materials used in bi-folds will affect their durability significantly. Aluminium is renowned for its strength and is also resistant to rust, corrosion and warping helping to enhance the product’s longevity.

When designing your own bi-fold, make sure you choose a material that can successfully handle future wear and tear to be confident it’ll last many years once installed in a home.

Double check the weight capacity

Depending on which bi-fold you choose to work with will also affect the maximum weight capacity.

Always remember to double check the weight capacity of the system you choose to work with. Failing to check if the hardware can handle the weight of the doors can put unnecessary strain on the hardware leading to premature wear, malfunctioning and could become a hazard for homeowners.

Designing a bi-fold with appropriate weight capacities means you can ensure smooth operation – helping to contribute to the overall quality and longevity of the product.

Identify weak spots

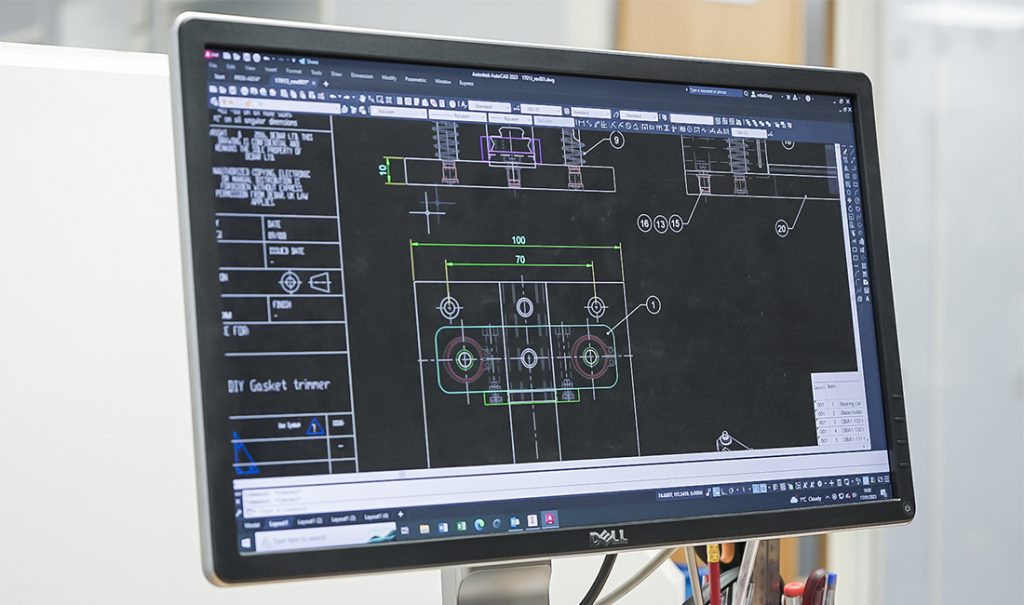

At Debar, we always use computer simulations to find and fix any weak spots within the system before it goes to market.

Finite element analysis (or FEA for short) plays a crucial role in optimising the design and ensuring long-lasting functionality. It allows engineers to simulate real-world stresses and strains placed on the doors and hardware to help uncover any areas which could lead to premature wearing or failure of the system.

Test again and again

One of the most important parts of manufacturing a bi-fold is rigorously testing the system. Test bi-fold doors for regular use, impact and different weather conditions to easily identify whether the final product is technically sound and functional.

Our team of experts are on hand to offer their guidance and assistance to ensure the bi-folding doors you design are robust, secure and deliver exceptional thermal performance.

Regularly check quality

When it comes to designing and manufacturing your own bi-fold system, quality should become the foundation for the product’s success.

As a bi-fold hardware manufacturer we have an absolute commitment to quality control which means all of our products are refined and tested to guarantee consistency and efficiency. It’s a great way to reduce the risk of errors or costly repairs further down the line, saving both valuable time and money – which is why we recommend other manufacturers to consider working in the same way.

Keep a close eye on the production quality with regular thorough inspections to feel confident high-quality manufacturing is conducted time and time again.

Provide clear installation and maintenance tips

While this may seem like an obvious point, clear installation tips create a smooth and successful installation. When the equipment needed and steps to follow are outlined in a simple step-by-step process, you’ll be sure to witness faster installation times, reduced material waste and ultimately more satisfied customers.

Clear installation and maintenance instructions not only ensure that bi-folds are installed properly but they also give installers the confidence to showcase their skills and expertise.

Always prioritise safety

Always remember to prioritise the safety of your users by looking at features in the bi-folding system to help prevent accidents once the doors are installed. For instance, sash panel catches and other finger-saver solutions which are perfect for reducing the risk of minor injuries.

Manufacturing quality bi-folding doors

Ultimately, we strongly believe that manufacturing bi-folding doors to the highest standards isn’t a luxury, it’s a necessity. Work with the best materials, test the system to ensure it can withstand regular use and a range of weather conditions, and put quality at the centre of the design. In doing so, your bi-fold will boast smooth and effortless operation and will deliver long-lasting performance for many years.

If you’re looking to design and manufacture a bi-folding system our team can help. As your partner of choice, we’ll share our knowledge so you can pick the right materials and components for your project to guarantee you see great results. Get in touch today to find out more.